Mochini oa MND-FS05 Lateral Raise o sebelisa tube e kholo ea tšepe e bōpehileng joaloka D e le foreimi, e leng se etsang hore lisebelisoa li be le boima bo eketsehileng. Sekoahelo se khabisitsoeng sa mohele se sebelisa motsoako oa aluminium 'me likarolo tsa motsamao li sebelisa tube e bataletseng ea oval e le foreimi, boholo ke 50 * 100 * T3mm. Tsena tsohle li etsa hore mochini o tiee ebile o motle.

Mochini oa MND-FS05 oa ho phahamisa maoto ka mahlakoreng o hlahisa li-deltoid le ho haha mahetla a maholo. Ntle le mahetla a matla le a maholo, melemo ea ho phahamisa maoto ka mahlakoreng e atoloha ho eketsa ho sisinyeha ha mahetla. Haeba u itlama ka nepo nakong eohle ea ho phahamisa maoto, karolo ea hau ea mantlha le eona e rua molemo, 'me mesifa e ka morao, matsoho le molala le eona e tla utloa khatello kamora li-sete tse 'maloa.

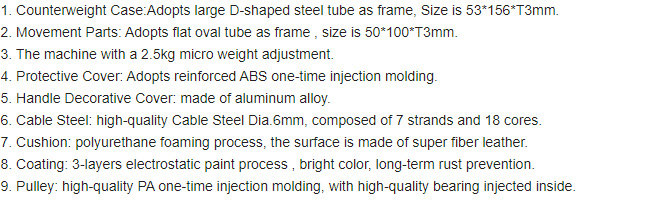

1. Nyeoe e Hanyetsanang le Boima: E amohela tube e kholo ea tšepe e bōpehileng joaloka D e le foreimi, Boholo ke 53 * 156 * T3mm.

2. Likarolo tsa Motsamao: E amohela tube e bataletseng e oval joalo ka foreimi, boholo ke 50 * 100 * T3mm.

3. Mochini o nang le phetoho ea boima bo bonyenyane ba 2.5kg.

4. Sekoahelo se Sireletsang: E amohela ho bōptjoa ha ABS e matlafalitsoeng hanngoe.

5. Sekoahelo sa Mokhabiso sa Mohele: se entsoe ka motsoako oa aluminium.

6. Tšepe ea Cable: Tšepe ea Cable ea boleng bo holimo ea Dia.6mm, e entsoe ka likhoele tse 7 le li-core tse 18.

7. Sekotjana: mokhoa oa ho ntša foam ka polyurethane, bokaholimo bo entsoe ka letlalo le nang le fiber e ngata.

8. Ho penta: Mokhoa oa pente ea electrostatic oa mekhahlelo e 3, 'mala o khanyang, thibelo ea mafome ea nako e telele.

9. Pulley: ho bopa ente ea PA ea boleng bo holimo hang, ka bearing ea boleng bo holimo e kenngoeng kahare.

Khamphani ea rona ke e 'ngoe ea bahlahisi ba kholo ka ho fetisisa ba lisebelisoa tsa boikoetliso Chaena, e nang le boiphihlelo ba lilemo tse 12 indastering ea boikoetliso. Boleng ba lihlahisoa tsa rona boa tšepahala, ho tloha lisebelisoa tse tala ho isa lihlahisoa tse felileng, li latela ka tieo litekanyetso tsa boleng ba machaba, mesebetsi eohle ea indasteri ebang ke ea ho tjheseletsa kapa ea ho fafatsa, ka nako e ts'oanang theko e utloahala haholo.